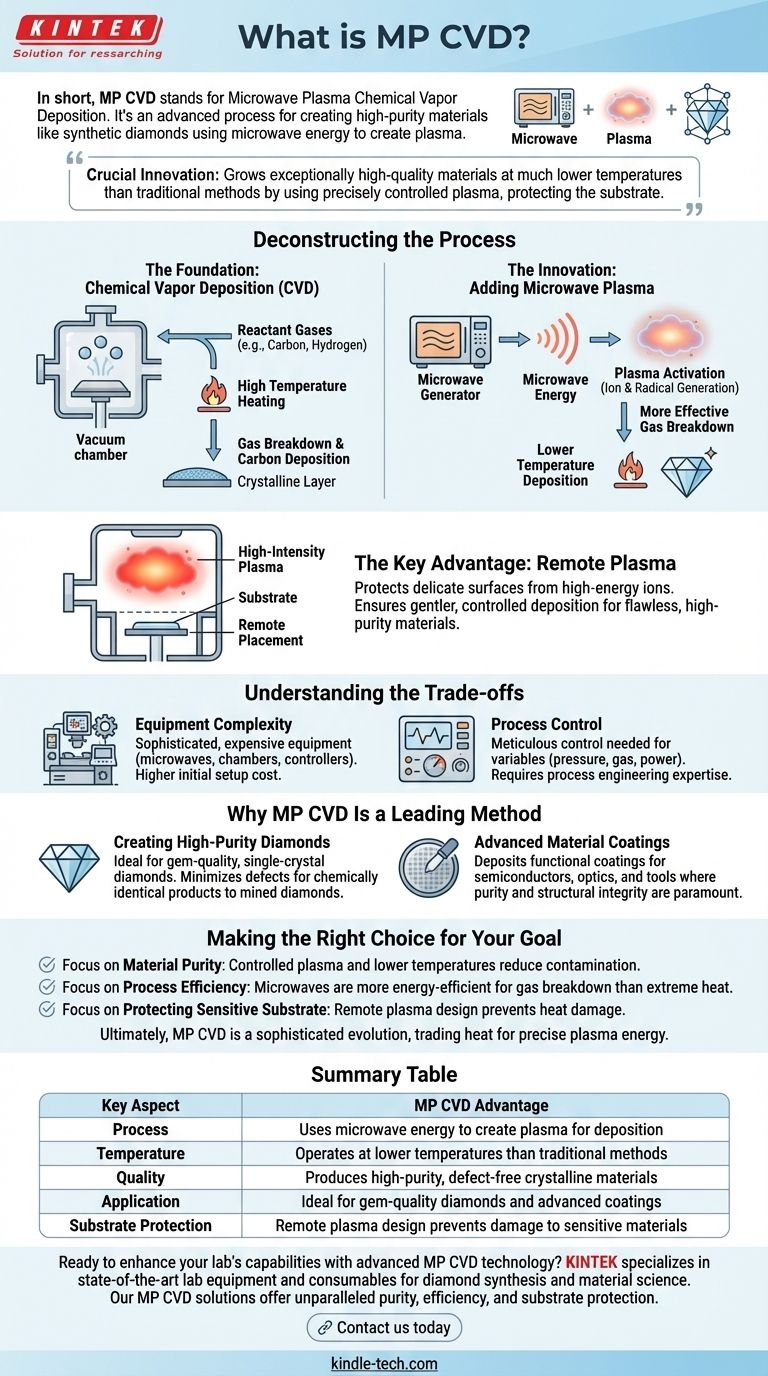

En resumen, MP CVD significa Deposición Química de Vapor por Plasma de Microondas (Microwave Plasma Chemical Vapor Deposition). Es un proceso altamente avanzado que se utiliza para crear diamantes sintéticos y otros materiales cristalinos de alta pureza dentro de un entorno de laboratorio controlado. Este método utiliza energía de microondas para excitar un gas a un estado de plasma, que luego se descompone y se deposita sobre un sustrato, capa por capa.

La innovación crucial de la MP CVD es su capacidad para cultivar materiales de calidad excepcionalmente alta a temperaturas mucho más bajas que los métodos tradicionales. Lo logra utilizando un plasma controlado con precisión para activar la reacción química, en lugar de depender del calor de fuerza bruta, lo que protege el sustrato de posibles daños.

Deconstruyendo el Proceso

Para comprender la MP CVD, es mejor desglosarla en sus componentes principales: el método fundamental (CVD) y la innovación clave (Plasma de Microondas).

La Base: Deposición Química de Vapor (CVD)

El proceso general de CVD implica colocar un sustrato, a menudo una pequeña semilla de diamante, dentro de una cámara de vacío.

Luego se introducen en esta cámara gases reactivos, típicamente una mezcla de una fuente de carbono como el metano y el hidrógeno.

La cámara se calienta a una temperatura muy alta, lo que hace que las moléculas de gas se descompongan y depositen sus átomos de carbono en el sustrato, construyendo lentamente una nueva capa cristalina.

La Innovación: Añadir Plasma de Microondas

La MP CVD mejora este proceso añadiendo energía de microondas. Esta energía "activa" los gases reactivos, convirtiéndolos en un plasma: una nube energizada de iones y radicales.

Este plasma es mucho más eficaz para descomponer las moléculas reactivas que el calor por sí solo. Esto permite que la deposición ocurra a temperaturas significativamente más bajas.

La Ventaja Clave: Plasma Remoto

Una característica crítica de muchos sistemas de MP CVD es que el sustrato no se coloca directamente dentro de la parte más intensa de la descarga de plasma.

Esta colocación "remota" protege la delicada superficie en crecimiento de ser dañada por iones de alta energía. Asegura una deposición más suave y controlada, lo cual es esencial para crear materiales impecables y de alta pureza.

Comprender las Compensaciones

Aunque es potente, el método MP CVD no está exento de complejidades. Es necesaria una comprensión clara de sus compensaciones para obtener una imagen completa.

Complejidad del Equipo

Los sistemas de MP CVD requieren equipos sofisticados y costosos, incluidos generadores de microondas, cámaras de vacío y controladores de flujo de gas precisos. Esto hace que la configuración inicial sea más costosa que los métodos de CVD térmico más simples.

Control del Proceso

Gestionar un plasma estable requiere un control meticuloso de variables como la presión, la composición del gas y la potencia de las microondas. Cualquier desviación puede afectar la calidad y uniformidad del producto final, lo que exige una experiencia significativa en ingeniería de procesos.

Por Qué la MP CVD es un Método Líder

Las ventajas del proceso MP CVD lo convierten en una técnica dominante, particularmente en la producción de diamantes sintéticos de alta calidad.

Creación de Diamantes de Alta Pureza

El entorno controlado y a menor temperatura es ideal para cultivar diamantes monocristalinos de calidad gema. Esto minimiza el riesgo de defectos estructurales o impurezas, lo que da como resultado un producto que es química y físicamente idéntico a un diamante extraído.

Recubrimientos de Materiales Avanzados

Más allá de los diamantes, la MP CVD se utiliza para depositar una amplia gama de recubrimientos funcionales. Estas películas delgadas se utilizan en semiconductores, óptica y herramientas resistentes al desgaste donde la pureza y la integridad estructural son primordiales.

Tomar la Decisión Correcta para su Objetivo

Comprender los principios de la MP CVD le permite reconocer su propósito en diferentes aplicaciones.

- Si su enfoque principal es la pureza del material: La MP CVD es superior porque el plasma controlado y las temperaturas más bajas reducen el riesgo de contaminación y fallas estructurales.

- Si su enfoque principal es la eficiencia del proceso: Usar microondas para generar un plasma es una forma más eficiente energéticamente de descomponer los gases precursores en comparación con depender únicamente del calor extremo.

- Si su enfoque principal es proteger un sustrato sensible: El diseño de plasma remoto es la característica crítica, que previene el daño por calor y asegura la integridad del material que se está recubriendo.

En última instancia, la MP CVD representa una evolución sofisticada de la ciencia de los materiales, cambiando el calor simple por energía de plasma precisa para lograr una calidad y un control inigualables.

Tabla Resumen:

| Aspecto Clave | Ventaja de la MP CVD |

|---|---|

| Proceso | Utiliza energía de microondas para crear plasma para la deposición |

| Temperatura | Opera a temperaturas más bajas que los métodos tradicionales |

| Calidad | Produce materiales cristalinos de alta pureza y sin defectos |

| Aplicación | Ideal para diamantes de calidad gema y recubrimientos avanzados |

| Protección del Sustrato | El diseño de plasma remoto previene daños a materiales sensibles |

¿Listo para mejorar las capacidades de su laboratorio con la tecnología avanzada de MP CVD? KINTEK se especializa en proporcionar equipos de laboratorio y consumibles de última generación para la síntesis de diamantes y la ciencia de los materiales. Nuestras soluciones de MP CVD ofrecen pureza, eficiencia y protección del sustrato inigualables para sus necesidades de investigación y producción. ¡Contáctenos hoy para discutir cómo nuestra experiencia puede acelerar su innovación en materiales!

Guía Visual

Productos relacionados

- Sistema de Reactor de Deposición Química de Vapor de Plasma de Microondas MPCVD para Laboratorio y Crecimiento de Diamantes

- Equipo de Deposición Química de Vapor CVD Sistema Horno de Tubo PECVD Deslizante con Gasificador Líquido Máquina PECVD

- Sistema de Reactor de Máquina MPCVD de Resonador Cilíndrico para Deposición Química de Vapor de Plasma de Microondas y Crecimiento de Diamantes de Laboratorio

- Equipo de horno de tubo de deposición química de vapor mejorada por plasma inclinado PECVD

- Cúpulas de Diamante CVD para Aplicaciones Industriales y Científicas

La gente también pregunta

- ¿Qué es el proceso de deposición química de vapor mejorada por plasma de microondas? Logre recubrimientos de baja temperatura y alta calidad

- ¿Cuáles son las ventajas y aplicaciones de MPCVD? El estándar de oro para el crecimiento de diamantes monocristalinos de alta pureza

- ¿Cómo se forma un diamante CVD? Una guía para la creación de diamantes cultivados en laboratorio

- ¿Puede un probador de diamantes diferenciar entre diamantes creados en laboratorio y diamantes naturales? La sorprendente verdad

- ¿Cómo se fabrican los diamantes de laboratorio CVD? Descubra la ciencia detrás de las gemas cultivadas en laboratorio

- ¿Los diamantes cultivados en laboratorio pasan la prueba del detector de diamantes? Sí, son químicamente idénticos.

- ¿Cuál es el uso del diamante CVD? Desbloquee un rendimiento superior en aplicaciones extremas

- ¿Cómo se prueba un diamante CVD? Verifique la autenticidad con informes de clasificación e inscripción láser