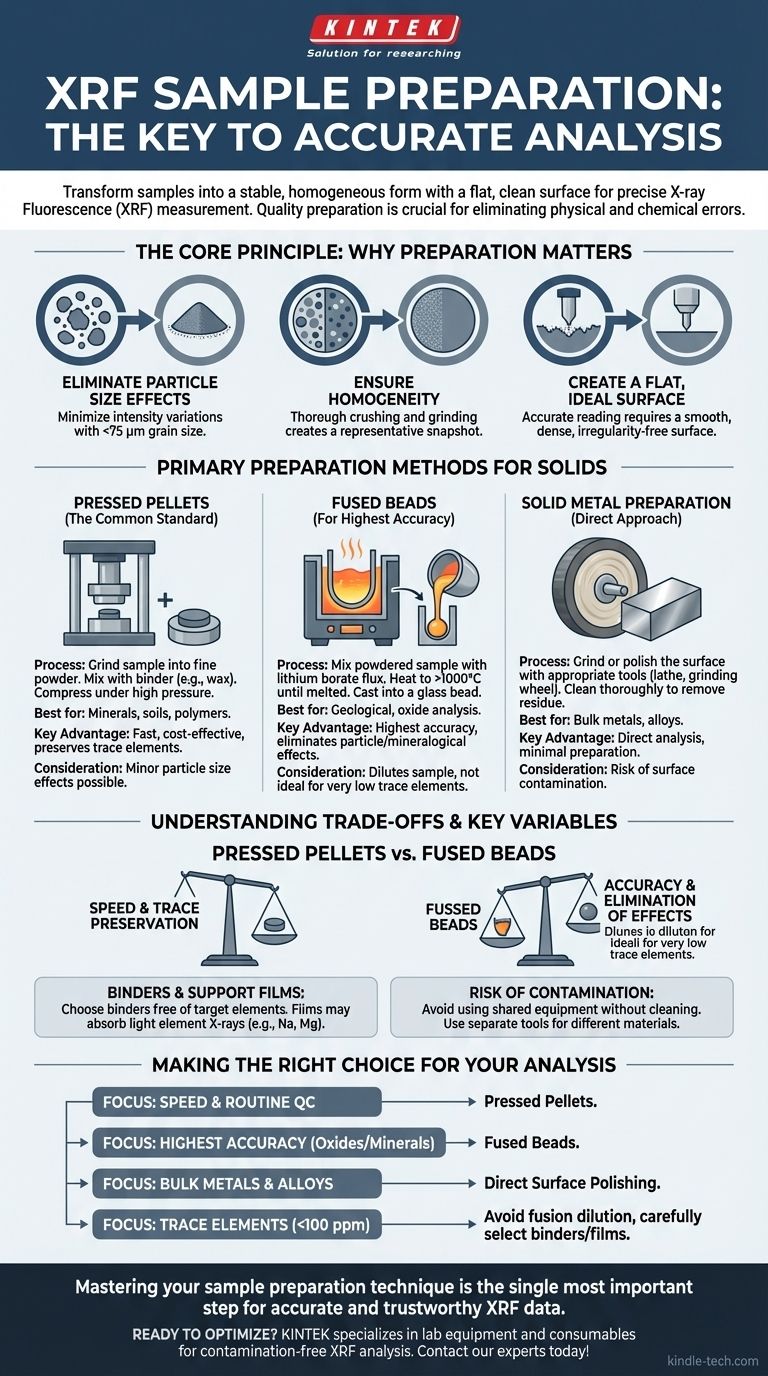

En resumen, las muestras se preparan para el análisis por fluorescencia de rayos X (FRX) transformándolas en una forma estable y homogénea con una superficie plana y limpia para la medición. Los métodos más comunes implican triturar y moler el material hasta obtener un polvo fino, que luego se prensa en una pastilla sólida o se funde con un fundente para formar una perla similar al vidrio.

La calidad de sus resultados de FRX está determinada más por la preparación de la muestra que por cualquier otro factor. El objetivo no es solo preparar una muestra, sino crear una que sea una instantánea perfectamente uniforme y representativa del material a granel original, eliminando así las fuentes de error físicas y químicas.

El principio fundamental: por qué la preparación es crítica

Antes de detallar los métodos, es fundamental comprender por qué la preparación es tan crucial para un análisis FRX preciso. El instrumento mide un volumen muy pequeño de la superficie de la muestra, por lo que esa superficie debe representar perfectamente todo el material.

Eliminación de los efectos del tamaño de partícula

La intensidad de los rayos X fluorescentes puede verse afectada por el tamaño, la forma y el empaquetamiento de los granos en una muestra.

Moler la muestra hasta obtener un polvo muy fino y uniforme, generalmente inferior a 75 micrómetros (µm), minimiza estos efectos del tamaño de partícula y garantiza que la medición sea consistente.

Garantizar una muestra representativa y homogénea

La mayoría de los materiales no son naturalmente homogéneos. La trituración y molienda mezclan el material a fondo, asegurando que la pequeña porción analizada por la FRX sea químicamente idéntica al material a granel.

Creación de una superficie plana e ideal

La geometría del instrumento FRX requiere una superficie perfectamente plana para una lectura precisa. Cualquier rugosidad o irregularidad puede dispersar los rayos X y sesgar los resultados, lo que hace que una superficie lisa y densa sea un requisito innegociable.

Métodos primarios de preparación para sólidos

Aunque los líquidos y los polvos sueltos pueden analizarse, los datos de mayor calidad para los materiales sólidos provienen de la creación de pastillas, perlas o superficies pulidas.

Método 1: Pastillas prensadas (El estándar común)

Este es el método más popular debido a su equilibrio entre velocidad, coste y calidad. Es excelente para una amplia gama de materiales, desde minerales y suelos hasta polímeros.

El proceso implica moler la muestra hasta obtener un polvo fino. Si el polvo no se adhiere bien por sí solo, se mezcla un aglutinante (como un polvo de cera). Luego, esta mezcla se coloca en un molde y se comprime bajo alta presión para formar una pastilla sólida y duradera.

Método 2: Perlas fundidas (Para la máxima precisión)

Para las aplicaciones que exigen la máxima precisión y exactitud, especialmente en el análisis geológico u de óxidos, la creación de una perla fundida es el método superior.

Aquí, la muestra en polvo se mezcla con un fundente de borato de litio. Luego, la mezcla se calienta en un crisol a más de 1000 °C hasta que se derrite, disolviendo completamente la muestra. El vidrio fundido se vierte luego en una perla sólida perfectamente plana. Este proceso elimina por completo los efectos del tamaño de partícula y la mineralogía.

Método 3: Preparación de metal sólido

Para analizar metales y aleaciones sólidas, el enfoque es mucho más directo. El objetivo es simplemente crear una superficie limpia y plana en el propio material a granel.

Esto se logra típicamente moliendo o puliendo la superficie con herramientas apropiadas, como un torno para metales blandos o una muela abrasiva para aleaciones duras. Luego, la superficie debe limpiarse para eliminar cualquier residuo o contaminación del proceso de preparación.

Comprensión de las compensaciones y variables clave

Elegir el método correcto requiere comprender los compromisos involucrados y los factores que pueden introducir errores en su análisis.

Pastillas prensadas frente a perlas fundidas

Las pastillas prensadas son rápidas y conservan la concentración de elementos traza. Sin embargo, todavía son susceptibles a efectos menores del tamaño de partícula y la mineralogía.

Las perlas fundidas eliminan por completo estos efectos físicos, lo que da como resultado una mayor precisión. La principal compensación es que el fundente diluye la muestra, lo que puede dificultar la medición de elementos presentes en concentraciones muy bajas. El proceso también es más complejo y requiere más tiempo.

El papel de los aglutinantes y las películas de soporte

Los aglutinantes son esenciales para crear pastillas duraderas a partir de polvos no cohesivos, pero también diluyen la muestra. Debe elegir un aglutinante que no contenga ninguno de los elementos que intenta medir.

De manera similar, si se utiliza una película de plástico delgada para soportar un polvo suelto, esa película puede absorber algunos de los rayos X, particularmente de los elementos más ligeros, lo que lleva a resultados inexactos para elementos como el Sodio (Na) o el Magnesio (Mg).

El riesgo de contaminación

La contaminación es un riesgo constante durante la preparación. El uso de equipos de molienda utilizados previamente para un tipo de muestra diferente puede introducir elementos extraños. De manera similar, el uso de limas separadas para limpiar diferentes aleaciones metálicas es fundamental para prevenir la contaminación cruzada.

Tomar la decisión correcta para su análisis

El método de preparación debe seleccionarse en función del tipo de muestra, los objetivos analíticos y los requisitos de precisión.

- Si su enfoque principal es la velocidad y el control de calidad rutinario: Las pastillas prensadas ofrecen el mejor equilibrio entre velocidad, coste y resultados fiables.

- Si su enfoque principal es la mayor precisión posible para óxidos o minerales: Las perlas fundidas son la opción definitiva, ya que eliminan los efectos físicos de la matriz.

- Si su enfoque principal es el análisis de metales o aleaciones a granel: El pulido directo de la superficie es el método más eficiente y apropiado.

- Si su enfoque principal es la medición de elementos traza (<100 ppm): Evite la fusión para prevenir la dilución y seleccione cuidadosamente aglutinantes y películas libres de sus elementos de interés.

En última instancia, dominar su técnica de preparación de muestras es el paso más importante que puede dar para producir datos de FRX precisos y fiables.

Tabla de resumen:

| Método de preparación | Ideal para | Ventaja clave | Consideración clave |

|---|---|---|---|

| Pastillas prensadas | Minerales, suelos, polímeros | Rápido, rentable, conserva elementos traza | Posibles efectos menores del tamaño de partícula |

| Perlas fundidas | Óxidos, muestras geológicas | Máxima precisión, elimina efectos de matriz | Diluye la muestra, no es ideal para elementos traza |

| Pulido de sólidos | Metales, aleaciones | Análisis directo, preparación mínima | Riesgo de contaminación superficial |

¿Listo para optimizar la preparación de sus muestras de FRX? KINTEK se especializa en equipos de laboratorio y consumibles para un análisis FRX preciso y libre de contaminación. Ya sea que necesite prensas de pastillas, fundentes de fusión o herramientas de pulido, nuestras soluciones garantizan que sus muestras estén perfectamente preparadas para obtener resultados precisos. Contacte con nuestros expertos hoy mismo para analizar las necesidades de su laboratorio.

Guía Visual

Productos relacionados

- Prensa Hidráulica de Laboratorio Prensa para Pellets para Baterías de Botón

- Prensa Hidráulica Automática de Laboratorio para Prensa de Pastillas XRF y KBR

- Prensa Hidráulica Manual de Alta Temperatura con Placas Calefactoras para Laboratorio

- Máquina de montaje de especímenes metalúrgicos para materiales y análisis de laboratorio

- Prensa de Calentamiento de Doble Placa para Laboratorio

La gente también pregunta

- ¿Qué papel juega una prensa hidráulica uniaxial de laboratorio en la preparación del cuerpo verde LATP? Guía esencial de conformado

- ¿Cuál es el propósito principal de usar una prensa hidráulica de laboratorio a 500 MPa? Optimizar la densidad de las baterías de estado sólido

- ¿Cuál es la función principal de una prensa hidráulica uniaxial en la fabricación de NiO-BCZYYb? Lograr cuerpos verdes de alta densidad

- ¿Cuáles son las limitaciones del curvado por rodillos? Comprender las ventajas y desventajas para su proyecto de conformado de metales

- ¿Qué precauciones de seguridad están asociadas con la operación de una prensa industrial? Garantizar la seguridad del operador y prevenir accidentes

- ¿Cuál es la diferencia entre una prensa neumática y una prensa hidráulica? Elija la fuerza adecuada para su aplicación

- ¿Cuál de los siguientes se utiliza para preparar la pastilla de muestra en espectroscopia IR? Bromuro de Potasio (KBr) Explicado

- ¿Cuáles son las partes de una máquina de prensado? Comprenda los componentes principales para su aplicación