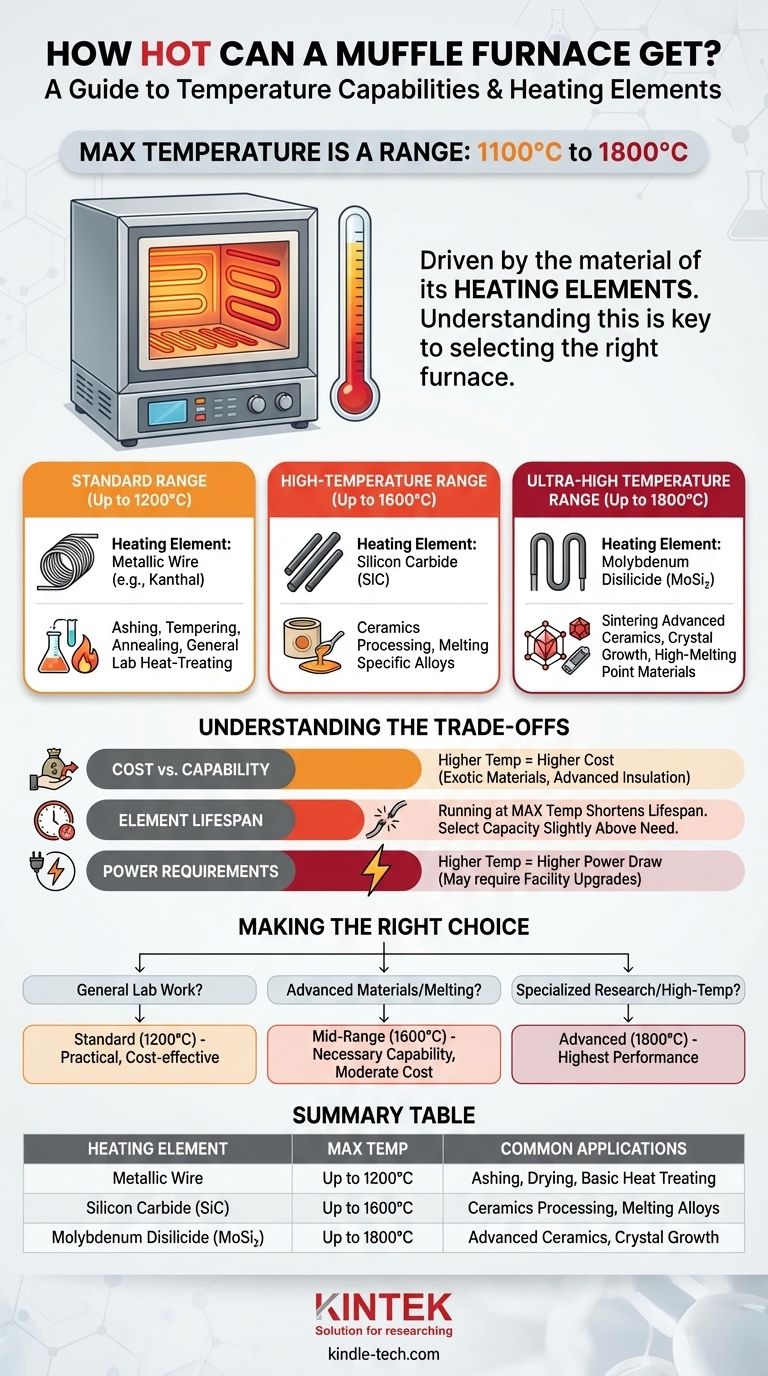

La temperatura máxima de un horno de mufla no es un valor único, sino un rango determinado por su diseño y componentes específicos. Si bien los modelos de laboratorio más comunes suelen alcanzar un máximo de 1100 °C a 1200 °C (2192 °F), los hornos altamente especializados construidos con materiales avanzados pueden alcanzar temperaturas tan altas como 1800 °C (3272 °F).

La temperatura máxima del horno está dictada casi en su totalidad por el material utilizado para sus elementos calefactores internos. Comprender esta relación es clave para seleccionar un horno que pueda satisfacer de manera segura y consistente las demandas de su aplicación específica de alta temperatura.

Por qué no existe una "temperatura máxima" única

Un "horno de mufla" es una categoría de equipo, no un producto estandarizado único. Los fabricantes diseñan estos hornos para diferentes propósitos, desde trabajos de laboratorio de uso general hasta procesos industriales especializados, y la capacidad de temperatura es el principal factor diferenciador.

El papel crítico de los elementos calefactores

El corazón de un horno de mufla eléctrico son sus elementos calefactores. Estos son los componentes que convierten la energía eléctrica en calor. Las propiedades físicas y químicas del material utilizado para estos elementos establecen un límite estricto en la temperatura de funcionamiento segura del horno.

Empujar un elemento más allá de su temperatura máxima diseñada hará que se degrade, oxide o incluso se derrita rápidamente, lo que provocará una falla prematura.

Un desglose de las capacidades por elemento calefactor

Las capacidades del horno se entienden mejor segmentándolas según el tipo de elemento calefactor que emplean.

Rango estándar (hasta 1200 °C): elementos de alambre metálico

Estos son los elementos calefactores más comunes y rentables, típicamente hechos de una aleación de hierro-cromo-aluminio (como Kanthal).

Son los caballos de batalla para una amplia gama de aplicaciones, incluyendo calcinación, templado, recocido y tratamiento térmico general de laboratorio.

Rango de alta temperatura (hasta 1600 °C): elementos de carburo de silicio (SiC)

Para procesos que requieren temperaturas más allá de los límites de los alambres metálicos, se utilizan elementos de carburo de silicio.

Estos son más robustos y pueden manejar aplicaciones más exigentes, como el procesamiento de ciertas cerámicas o la fusión de algunos metales y aleaciones.

Rango de temperatura ultra alta (hasta 1800 °C): elementos de disiliciuro de molibdeno (MoSi₂)

Estos son los elementos de mayor rendimiento comúnmente disponibles. Se reservan para investigación especializada y procesos industriales.

Las aplicaciones incluyen la sinterización de cerámicas avanzadas, el crecimiento de cristales y el trabajo con materiales que tienen puntos de fusión extremadamente altos.

Comprendiendo las compensaciones

Elegir un horno con una clasificación de temperatura más alta implica más que solo rendimiento; conlleva importantes implicaciones prácticas y financieras.

Costo vs. Capacidad

La relación es directa: una temperatura máxima más alta requiere materiales de elementos más exóticos y caros y un aislamiento más avanzado. Esto resulta en un precio de compra inicial significativamente más alto para el horno.

Vida útil del elemento y condiciones de funcionamiento

Hacer funcionar un horno constantemente a su temperatura máxima nominal absoluta acortará la vida útil de sus elementos calefactores. Para una mayor longevidad, a menudo se recomienda seleccionar un horno con una temperatura máxima ligeramente superior a la temperatura de proceso requerida.

Requisitos de energía e instalaciones

Los hornos de mayor temperatura consumen significativamente más energía eléctrica. Un horno de 1800 °C tendrá requisitos de energía y ventilación mucho más exigentes que un modelo de laboratorio estándar de 1200 °C, lo que puede requerir mejoras en las instalaciones.

Tomando la decisión correcta para su objetivo

Seleccione un horno basándose en los requisitos específicos de su proceso, no solo en el número más alto.

- Si su enfoque principal es el trabajo de laboratorio general (por ejemplo, calcinación, secado, tratamiento térmico básico): Un horno estándar con elementos de alambre metálico que alcanzan hasta 1200 °C es la opción más práctica y rentable.

- Si su enfoque principal es el procesamiento de materiales avanzados o la fusión de aleaciones de baja temperatura: Un horno de rango medio con elementos de carburo de silicio (SiC) de hasta 1600 °C proporciona la capacidad necesaria sin un costo excesivo.

- Si su enfoque principal es la investigación especializada con cerámicas de alta temperatura o metales específicos: Necesitará un horno avanzado con elementos de disiliciuro de molibdeno (MoSi₂) capaces de alcanzar los 1800 °C.

En última instancia, hacer coincidir la tecnología del elemento calefactor del horno con sus requisitos de temperatura específicos es clave para un proceso exitoso y eficiente.

Tabla resumen:

| Tipo de elemento calefactor | Rango de temperatura máxima | Aplicaciones comunes |

|---|---|---|

| Alambre metálico (por ejemplo, Kanthal) | Hasta 1200 °C | Calcinación, secado, tratamiento térmico básico |

| Carburo de silicio (SiC) | Hasta 1600 °C | Procesamiento de cerámicas, fusión de aleaciones |

| Disiliciuro de molibdeno (MoSi₂) | Hasta 1800 °C | Cerámicas avanzadas, crecimiento de cristales |

¿Necesita un horno de mufla que se ajuste a sus requisitos de temperatura? KINTEK se especializa en equipos y consumibles de laboratorio, proporcionando hornos con la tecnología de elementos calefactores adecuada para su proceso específico, desde trabajos de laboratorio generales hasta investigación de materiales avanzados. Contáctenos hoy para discutir su aplicación y obtener orientación experta sobre el horno ideal para las necesidades de su laboratorio.

Guía Visual

Productos relacionados

- Horno de Mufla de Laboratorio con Elevación Inferior

- Horno de mufla de 1800℃ para laboratorio

- Horno de mufla de 1700℃ para laboratorio

- Horno de mufla de 1400 ℃ para laboratorio

- Horno de Tubo de Laboratorio de Alta Temperatura de 1400℃ con Tubo de Alúmina

La gente también pregunta

- ¿Cómo se utilizan los hornos de precisión para el curado de PDMS? Logre un reticulado superior para sustratos de alto rendimiento

- ¿Qué requisitos técnicos específicos debe cumplir un horno de caja de alta temperatura para la perovskita LSTH? Lograr 1450 °C de pureza

- ¿Qué papel juega un horno mufla de caja en el tostado oxidativo? Mejore la eficiencia de su procesamiento de sulfuro de zinc

- ¿Cómo se utilizan los hornos mufla o de atmósfera en la síntesis de Y-Ti-Zr-O? Optimice sus precursores de acero ODS

- ¿Cuál es el rango de calentamiento de un horno de mufla? De 800°C a 1800°C para las necesidades de su laboratorio

- ¿Cuál es el propósito principal de usar hornos de sinterización a alta temperatura para el postprocesamiento de SLM? Desbloquear el máximo rendimiento

- ¿Qué papel juega un horno de alta temperatura en las membranas cerámicas de nanofiltración? Sinterización de Precisión para el Control de Poros

- ¿Cuál es el papel de un horno de alta temperatura en la preparación de catalizadores de dolomita? Lograr la activación térmica a 850°C