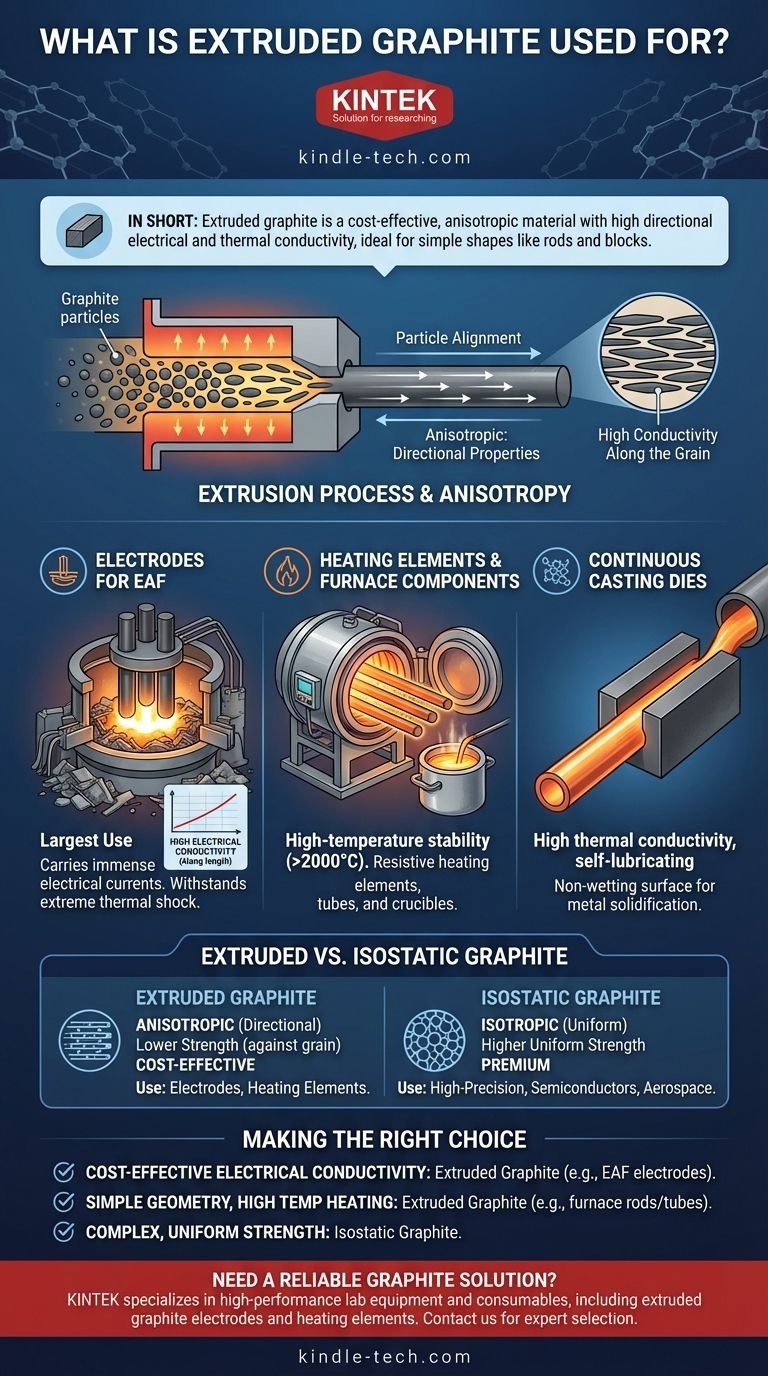

En resumen, el grafito extruido se utiliza principalmente para aplicaciones donde la rentabilidad y la alta conductividad eléctrica o térmica en una dirección específica son fundamentales. Sus usos más comunes son como electrodos en hornos de arco eléctrico para el reciclaje de acero, elementos calefactores en hornos industriales de alta temperatura y crisoles para fundir metales.

El principio fundamental a comprender es que el proceso de extrusión alinea las partículas de grafito, creando un material con excelentes propiedades direccionales. Esto lo convierte en la opción ideal y económica para formas más sencillas como varillas y bloques, pero menos adecuado para componentes complejos que requieren una resistencia uniforme en todas las direcciones.

Las propiedades definitorias del grafito extruido

Para comprender sus aplicaciones, primero debemos entender cómo se fabrica el grafito extruido y qué características resultan de ese proceso. No es un material de uso general; es una herramienta especializada para trabajos específicos.

El proceso de extrusión y la anisotropía

El grafito extruido se produce mezclando coque de petróleo y un aglutinante, calentándolo y forzándolo a través de una matriz para formar una forma, generalmente una varilla o un bloque.

Este proceso obliga a las partículas de grafito planas y en forma de placa a alinearse paralelas a la dirección de extrusión. Esta alineación crea un material que es anisotrópico, lo que significa que sus propiedades son diferentes cuando se miden a lo largo de la veta en comparación con en contra de la veta.

Conductividad direccional

La principal consecuencia de esta anisotropía es una excelente conductividad eléctrica y térmica a lo largo de la longitud de la forma extruida (a favor de la veta). Las partículas alineadas crean un camino eficiente para que viajen la electricidad y el calor.

La conductividad es significativamente menor cuando se mide a través de la veta, un factor crucial en el diseño de ingeniería.

Rentabilidad

En comparación con otros métodos de producción de grafito sintético, como el prensado isostático, la extrusión es un proceso de fabricación de mayor volumen y más económico. Esto lo convierte en la opción predeterminada para aplicaciones que consumen grandes cantidades de grafito.

Aplicaciones principales en detalle

La combinación única de conductividad, estabilidad a alta temperatura y rentabilidad hace que el grafito extruido sea indispensable en varias industrias clave.

Electrodos para hornos de arco eléctrico (EAF)

Este es el mayor uso individual del grafito extruido. Se utilizan electrodos de grafito masivos, a menudo de más de dos pies de diámetro, para transportar inmensas corrientes eléctricas a los hornos de arco eléctrico.

La corriente funde la chatarra de acero como parte del proceso de reciclaje. El grafito extruido es el único material que puede proporcionar la conductividad eléctrica requerida y soportar el choque térmico extremo de este entorno a un costo aceptable.

Elementos calefactores y componentes de hornos

En hornos de vacío o atmósfera inerte que operan a temperaturas muy altas, las varillas y tubos de grafito extruido se utilizan a menudo como elementos calefactores resistivos.

Su capacidad para mantener la resistencia y conducir electricidad a temperaturas muy superiores a los 2000 °C es fundamental. También se les da forma de crisoles para procesos metalúrgicos que implican la fusión de metales no ferrosos.

Matrices de colada continua

En la producción de metales como el cobre y el aluminio, el metal fundido a menudo se tira a través de una matriz para formar varillas, tubos y otras formas.

El grafito extruido es un material excelente para estas matrices debido a su alta conductividad térmica (que ayuda a solidificar el metal), su naturaleza autolubricante y el hecho de que la mayoría de los metales fundidos no mojan su superficie.

Comprender las compensaciones: grafito extruido frente a grafito isostático

Elegir el tipo correcto de grafito es fundamental. La alternativa más común al grafito extruido es el grafito isostático, que sirve para un propósito muy diferente.

Anisotropía frente a isotropía

Como hemos cubierto, el grafito extruido es anisotrópico. Su resistencia y conductividad son direccionales.

El grafito isostático se fabrica presionando polvo de grafito desde todas las direcciones a la vez, lo que da como resultado una orientación aleatoria de las partículas. Esto lo hace isotrópico, lo que significa que sus propiedades son uniformes y consistentes en todas las direcciones.

Estructura de grano y resistencia

El grafito isostático tiene una estructura de grano mucho más fina y una mayor resistencia mecánica. Su uniformidad lo hace ideal para mecanizar componentes intrincados y de alta precisión que no pueden tener puntos débiles.

El grafito extruido tiene una estructura de grano más grande y una menor resistencia mecánica, particularmente en contra de la veta. No es adecuado para piezas estructurales complejas que experimentan tensión multidireccional.

Costo y rendimiento

Esta es la compensación esencial. El grafito extruido es el caballo de batalla rentable. El grafito isostático es un material premium de alto rendimiento utilizado en aplicaciones avanzadas y exigentes como la fabricación de semiconductores, reactores nucleares y componentes aeroespaciales.

Tomar la decisión correcta para su objetivo

Los requisitos específicos de su aplicación en cuanto a rendimiento, geometría y costo determinarán qué material es el apropiado.

- Si su enfoque principal es la conductividad eléctrica rentable para procesos a gran escala: El grafito extruido es el estándar de la industria para aplicaciones como electrodos de hornos de arco eléctrico.

- Si su enfoque principal son los elementos calefactores de alta temperatura con geometrías simples: El grafito extruido ofrece el mejor equilibrio entre rendimiento y costo para componentes de horno como varillas y tubos.

- Si su enfoque principal son componentes complejos que requieren resistencia uniforme y detalles finos: Debe especificar un material isotrópico de mayor calidad, como el grafito isostático.

En última instancia, la selección del material correcto comienza con la comprensión de que no todo el grafito es igual.

Tabla de resumen:

| Propiedad | Grafito extruido | Grafito isostático |

|---|---|---|

| Estructura | Anisotrópico (direccional) | Isotrópico (uniforme) |

| Uso principal | Electrodos, elementos calefactores, crisoles | Componentes de alta precisión, semiconductores |

| Costo | Rentable | Premium |

| Resistencia | Direccional, menor en contra de la veta | Alta, uniforme en todas las direcciones |

¿Necesita una solución de grafito fiable para su aplicación industrial o de laboratorio? KINTEK se especializa en equipos y consumibles de laboratorio de alto rendimiento, incluidos componentes de grafito extruido como electrodos y elementos calefactores. Nuestros expertos pueden ayudarle a seleccionar el material adecuado para una conductividad rentable y una estabilidad a alta temperatura. Contáctenos hoy para discutir sus necesidades específicas y mejorar la eficiencia de su proceso con las soluciones de confianza de KINTEK.

Guía Visual

Productos relacionados

- Horno de grafización al vacío de grafito de alta temperatura horizontal

- Horno de grafito para vacío y descarga inferior para materiales de carbono

- Crisol de grafito puro de alta pureza para evaporación

- Horno de Mufla de 1200℃ para Laboratorio

- Horno de mufla de 1700℃ para laboratorio

La gente también pregunta

- ¿Qué factores deben considerarse al seleccionar un material para aplicaciones de alta temperatura? Una guía para el rendimiento a largo plazo

- ¿Cuál es el efecto de la densidad en la sinterización? Logre una calidad superior y precisión dimensional

- ¿Cuáles son las ventajas y desventajas de la carburación? Aumenta la resistencia al desgaste y la resistencia a la fatiga

- ¿Qué materiales deben ser tratados térmicamente? Mejorando el rendimiento para aplicaciones exigentes

- ¿Cuáles son los productos de la pirólisis del caucho? Transformando neumáticos usados en combustible, negro de humo y acero

- ¿Cuáles son las aplicaciones industriales de la filtración? La guía esencial de los procesos de separación

- ¿Qué es la fusión en FRX? Logre una precisión inigualable en el análisis elemental

- ¿Qué papel juega el congelador ULT adecuado en el éxito de un laboratorio? Asegurando sus muestras más valiosas