Descripción general de los hornos de mufla

Tipos y usos

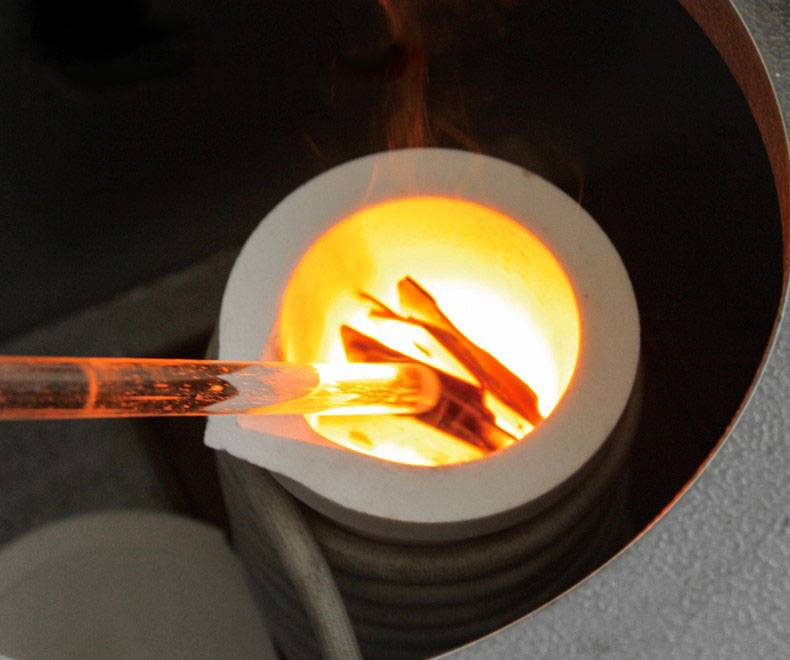

Los hornos de mufla, a menudo denominados hornos de cenizas de alta temperatura, son equipos de calentamiento muy versátiles que encuentran aplicaciones en un amplio espectro de industrias. Estos hornos son indispensables en tratamiento térmico donde facilitan el calentamiento y enfriamiento controlados de materiales para lograr transformaciones físicas y químicas específicas. En el sector farmacéutico los hornos de mufla se utilizan para procesos como la esterilización y la pirólisis, garantizando la pureza y eficacia de los medicamentos.

En química analítica estos hornos desempeñan un papel crucial en la preparación de muestras, sobre todo en técnicas como la incineración, en la que los materiales orgánicos se convierten en residuos inorgánicos para su posterior análisis. Para análisis de la calidad del carbón los hornos de mufla se emplean para determinar el contenido de cenizas y el valor calorífico de las muestras de carbón, proporcionando datos críticos para la producción de energía y las evaluaciones medioambientales.

Metal sinterización también se benefician de los hornos de mufla, que ayudan a compactar los polvos metálicos en formas sólidas con propiedades mecánicas mejoradas. Del mismo modo, tratamiento térmico de los metales para modificar su microestructura y mejorar su dureza, resistencia y resistencia al desgaste.

En el ámbito de la cocción de cerámica los hornos de mufla son esenciales para alcanzar las altas temperaturas necesarias para vitrificar la cerámica, garantizando su durabilidad y sus cualidades estéticas. Por último, en investigación experimental estos hornos ofrecen un medio fiable para llevar a cabo experimentos a alta temperatura, apoyando los avances en diversas disciplinas científicas.

Características de rendimiento

Los hornos de mufla están diseñados para ofrecer una serie de características de rendimiento que satisfacen diversas necesidades de laboratorio. Estos hornos son capaces de funcionar dentro de un amplio rango de temperaturas, que a menudo superan los 1.000 °C, lo que los hace adecuados para aplicaciones de alta temperatura como la cocción de cerámica y la sinterización de metales. Las velocidades de calentamiento de estos hornos son notablemente rápidas, lo que permite procesos térmicos rápidos que pueden reducir significativamente los tiempos de los ciclos experimentales.

El control preciso de la temperatura es otra característica crítica, ya que garantiza que el horno pueda mantener temperaturas exactas, lo que es esencial para experimentos que requieren una gran precisión. Este nivel de control se consigue a menudo mediante sistemas avanzados de control de la temperatura que ofrecen una precisión de ±1 °C o superior, lo que los hace ideales para la química analítica y otras aplicaciones sensibles.

Los volúmenes de las cámaras de los hornos de mufla son personalizables, lo que permite a los laboratorios seleccionar el tamaño adecuado en función de sus necesidades específicas. Tanto si se trata de muestras pequeñas como de grandes lotes, la flexibilidad en el diseño de la cámara garantiza que el horno pueda adaptarse a diversas configuraciones experimentales.

Algunos modelos avanzados incorporan cámaras de fibra cerámica de bajo consumo, que no sólo mejoran la eficiencia del horno, sino que también contribuyen a su durabilidad. Estas cámaras están diseñadas para retener el calor con mayor eficacia, lo que reduce el consumo de energía y prolonga la vida útil del horno. Esta combinación de eficiencia energética y durabilidad hace que las cámaras de fibra cerámica sean la opción preferida de muchos laboratorios.

Características principales

Los hornos de mufla se distinguen por varias características clave que los hacen adecuados para una gran variedad de aplicaciones industriales y de laboratorio. Estas características no sólo mejoran la funcionalidad del horno, sino que también garantizan la seguridad y la eficacia de su funcionamiento.

Una de las características más destacadas es el cuerpo de diseño dividido que facilita el mantenimiento y la reparación. Este diseño suele separar la cámara de calentamiento del panel de control, lo que reduce el riesgo de riesgos eléctricos y simplifica la sustitución de componentes como los elementos calefactores.

Los controladores inteligentes son otro componente fundamental, ya que ofrecen automatización y precisión avanzadas. Estos controladores pueden programarse para gestionar ciclos de calentamiento complejos, garantizando que el horno funcione dentro del rango de temperatura y la duración deseados. Suelen disponer de interfaces fáciles de usar, que facilitan la configuración y supervisión del horno incluso a los operarios más novatos.

Los elementos calefactores duraderos son esenciales para mantener un rendimiento constante durante largos periodos. Estos elementos, a menudo fabricados con materiales de alta calidad como carburo de silicio o disiliciuro de molibdeno, pueden soportar altas temperaturas sin degradarse, lo que garantiza un calentamiento fiable y una mayor vida útil del horno.

Los avanzados sistemas de control de la temperatura proporcionan una regulación precisa de la temperatura interna. Esto es crucial para los experimentos que requieren condiciones de temperatura exactas, como los de química analítica o ciencia de materiales. Muchos hornos modernos ofrecen una uniformidad de temperatura de ±1 °C, lo que es vital para obtener resultados uniformes.

La seguridad es una preocupación primordial en los entornos de laboratorio, y los hornos de mufla están equipados con varias características de seguridad . Pueden incluir mecanismos de desconexión automática, alarmas de sobretemperatura y botones de parada de emergencia, lo que garantiza que el horno pueda funcionar con seguridad incluso en condiciones no supervisadas.

Por último, la posibilidad de personalizar las cámaras del horno permite flexibilidad en el manejo de diferentes tipos y tamaños de muestras. Tanto si necesita una cámara pequeña para los análisis rutinarios como una más grande para el procesamiento a granel, las opciones personalizables garantizan que el horno pueda adaptarse para satisfacer necesidades específicas.

En resumen, la combinación de estas características hace que los hornos de mufla sean una opción versátil y fiable para una amplia gama de aplicaciones de laboratorio.

Selección del horno de mufla adecuado

Requisitos de temperatura

A la hora de seleccionar un horno de mufla, es fundamental tener en cuenta el rango de temperatura necesario para sus experimentos específicos. Los distintos procesos exigen temperaturas extremas variables, y comprender estas necesidades es esencial para elegir el equipo adecuado.

Por ejemplo, el secado de materiales suele requerir temperaturas moderadas, generalmente entre 500 y 600 °C. Este rango garantiza un secado eficaz de los materiales. Este rango garantiza un secado eficaz de los materiales sin degradación térmica. Por otro lado, los procesos de cocción de cerámica suelen requerir temperaturas mucho más elevadas, que a veces alcanzan los 1.700 °C. Estas temperaturas elevadas son necesarias para conseguir la temperatura deseada. Estas elevadas temperaturas son necesarias para conseguir las propiedades estructurales y físicas deseadas en la cerámica.

| Tipo de proceso | Rango de temperatura | Importancia del control de la temperatura |

|---|---|---|

| Secado de materiales | 500-600°C | Garantiza un secado eficaz sin degradación térmica |

| Cocción de cerámica | Hasta 1700°C | Consigue las propiedades estructurales y físicas deseadas |

Comprender estos requisitos de temperatura ayuda a seleccionar un horno de mufla que pueda satisfacer con precisión las necesidades térmicas de sus experimentos, garantizando resultados óptimos y la eficiencia del proceso.

Tamaño de la cámara del horno

Al seleccionar un horno de mufla, el tamaño de la cámara es una consideración crítica que afecta directamente a la eficacia y los resultados de sus experimentos. El tamaño de la cámara debe ser proporcional al tamaño y número de muestras que pretende procesar. Las muestras más grandes, o un mayor volumen de muestras, requieren una cámara de horno más grande para acomodar el espacio necesario para un calentamiento y procesamiento uniformes.

Para determinar el tamaño adecuado de la cámara, comience por evaluar las dimensiones de sus muestras típicas. Considere si estas muestras son estándar o inusualmente grandes. Por ejemplo, si trabaja a menudo con piezas cerámicas grandes o con varias muestras simultáneamente, será indispensable una cámara más grande. Por el contrario, las cámaras más pequeñas son adecuadas para muestras más compactas o individuales, optimizando el espacio y la eficiencia energética.

Otro factor a tener en cuenta es el volumen de muestras que procesa con regularidad. Un mayor rendimiento puede requerir una cámara más grande para evitar recargas frecuentes y mantener un funcionamiento continuo. Esto es especialmente importante en sectores en los que el procesamiento por lotes es habitual, como los laboratorios farmacéuticos o de química analítica.

En resumen, la elección del tamaño de la cámara del horno debe guiarse por las necesidades específicas de su laboratorio. Evaluando cuidadosamente el tamaño y el volumen de sus muestras, podrá seleccionar un horno de mufla con una cámara que garantice un rendimiento y una eficacia óptimos en sus experimentos.

Uniformidad de temperatura

Para realizar experimentos precisos, es crucial seleccionar un horno con alta uniformidad de temperatura. Esta uniformidad se mide normalmente por la variación de temperatura en toda la zona caliente, a menudo expresada como un rango (por ejemplo, ±20 °F). Por ejemplo, los hornos conformes a la norma AMS 2750D, Clase 4, ofrecen una uniformidad de temperatura de ±20°F dentro del intervalo de 300-600°F. Este nivel de precisión garantiza que todas las muestras dentro de la cámara del horno experimenten un calentamiento uniforme, lo que es esencial para obtener resultados reproducibles.

Sin embargo, no todas las aplicaciones requieren una uniformidad tan estricta. El secado general de materiales, por ejemplo, puede no exigir el mismo nivel de precisión. En estos casos, un horno con especificaciones de uniformidad de temperatura más amplias puede ser suficiente, reduciendo los costes sin comprometer la eficacia global del proceso.

La uniformidad de la temperatura en un horno depende en gran medida del diseño de la zona caliente, incluido el aislamiento y la disposición de los elementos calefactores. La uniformidad óptima se consigue mediante un diseño cuidadoso que reduzca al mínimo los huecos y aberturas, sobre todo en puntos críticos como los orificios de salida del gas. Además, un sistema de calentamiento multizona puede ayudar a ajustar dinámicamente la potencia de entrada, garantizando una distribución más uniforme de la temperatura en toda la cámara.

| Rango de temperatura | Uniformidad (±°F) | Clase AMS 2750D |

|---|---|---|

| 300-600°F | 20 | Clase 4 |

| 600-900°F | 15 | Clase 3 |

| 900-2500°F | 10 | Clase 2 |

La comprensión de estas especificaciones puede guiarle en la elección del horno adecuado para las necesidades específicas de su laboratorio, equilibrando la precisión con la practicidad.

Velocidad de aumento de temperatura

Al elegir un horno de mufla para sus necesidades de laboratorio, la velocidad de aumento de la temperatura es un factor crítico a tener en cuenta, especialmente para los procesos que requieren ciclos térmicos rápidos. Un horno con una tasa de aumento de temperatura rápida puede reducir significativamente el tiempo necesario para alcanzar la temperatura de funcionamiento deseada, acelerando así los plazos experimentales y mejorando la eficiencia general.

Para aplicaciones como la sinterización rápida o los tratamientos térmicos rápidos, es indispensable disponer de un horno capaz de alcanzar gradientes de temperatura elevados en un periodo corto. Estos procesos térmicos rápidos exigen equipos capaces de pasar rápidamente de la temperatura ambiente a la operativa, garantizando que las propiedades del material se alteren en el plazo requerido.

Sin embargo, es importante tener en cuenta que no todos los procesos de laboratorio requieren un rápido aumento de la temperatura. La sinterización rutinaria, por ejemplo, puede no requerir esta característica, ya que a menudo implica un calentamiento prolongado a una temperatura constante. En estos casos, un horno con una velocidad de aumento de temperatura más moderada puede ser suficiente, equilibrando el rendimiento con la rentabilidad.

| Tipo de proceso | Velocidad de aumento de temperatura requerida |

|---|---|

| Procesos térmicos rápidos | Alta (rápido aumento de la temperatura) |

| Sinterización rutinaria | Moderado (Aumento constante de la temperatura) |

En resumen, aunque un aumento rápido de la temperatura puede cambiar las reglas del juego en determinadas aplicaciones de laboratorio, no es esencial en todos los casos. Una cuidadosa consideración de sus necesidades experimentales específicas le ayudará a determinar el equilibrio óptimo entre velocidad y coste.

Precisión de control

Para los experimentos que requieren un control exacto de la temperatura, es imprescindible seleccionar hornos con una alta precisión, normalmente de ±1 °C o superior. Este nivel de precisión garantiza que las condiciones térmicas se mantengan constantes y dentro de los parámetros deseados, lo cual es crucial para experimentos con materiales sensibles o reacciones químicas precisas.

| Nivel de precisión | Aplicaciones típicas |

|---|---|

| ±1°C o superior | Química analítica, investigación farmacéutica y estudios experimentales que requieren un control exacto de la temperatura. |

| ±5°C o superior | Tratamientos generales de calentamiento, secado de materiales y procesos rutinarios de sinterización. |

Por el contrario, es posible que los tratamientos térmicos generales, como el secado de materiales o la sinterización rutinaria, no requieran una precisión tan estricta. Estos procesos suelen tolerar un rango más amplio de variabilidad de la temperatura, por lo que los hornos con un control menos preciso son suficientes para sus necesidades. Por lo tanto, la elección del horno debe ajustarse a los requisitos específicos del experimento para garantizar tanto la eficiencia como la precisión.

Material del horno

Al seleccionar un horno de mufla, el material de la solera es un factor crítico que influye directamente en el rendimiento y la longevidad del horno. Los dos materiales principales que se utilizan para las soleras son la fibra cerámica y el ladrillo refractario, cada uno de los cuales ofrece distintas ventajas adaptadas a diferentes aplicaciones.

Las soleras de fibra cerámica son famosas por su capacidad de calentamiento rápido y su eficiencia energética. Estos hogares están compuestos de materiales ligeros y aislantes que permiten cambios rápidos de temperatura, lo que los hace ideales para procesos que requieren ciclos de calentamiento frecuentes o rápidos. Su diseño energéticamente eficiente ayuda a reducir los costes operativos, lo que resulta especialmente beneficioso para los laboratorios en los que el consumo de energía es una preocupación clave.

Por otro lado, las soleras de ladrillo refractario están fabricadas para soportar temperaturas extremas y son más duraderas para aplicaciones de alta temperatura. Estos hornos están fabricados con materiales que pueden soportar una exposición prolongada a altas temperaturas sin degradarse, lo que los hace adecuados para operaciones que exigen un procesamiento continuo a altas temperaturas, como la cocción de cerámica o la sinterización de metales. Aunque pueden tardar más en calentarse que los hogares de fibra cerámica, su mayor durabilidad garantiza una vida útil más larga y un rendimiento constante en condiciones exigentes.

La elección entre estos materiales depende de los requisitos específicos de los procesos de su laboratorio. Para los experimentos que requieren un calentamiento rápido y eficiencia energética, los hogares de fibra cerámica son la opción preferida. Sin embargo, para aplicaciones que implican operaciones continuas a alta temperatura, los hornos de ladrillos refractarios ofrecen la robustez y fiabilidad necesarias.

Características adicionales

Al seleccionar un horno de mufla, es fundamental tener en cuenta las características que pueden mejorar la funcionalidad y la eficiencia de sus experimentos. Los controles programables son especialmente beneficiosos para los experimentos que requieren tratamientos térmicos precisos de varias etapas. Estos controles permiten personalizar los perfiles de calentamiento, garantizando que cada etapa del proceso se ejecute con precisión y coherencia.

Las alarmas automáticas son otra característica esencial, ya que proporcionan notificaciones en tiempo real para eventos críticos como alcanzar una temperatura específica, fluctuaciones de energía o fallos del sistema. De este modo se garantiza la rápida resolución de cualquier problema, minimizando el riesgo de errores experimentales o daños en el equipo.

Para experimentos con materiales sensibles o procesos en los que el tiempo es un factor crítico funciones como monitorización remota y registro de datos pueden tener un valor incalculable. Estas funciones le permiten realizar un seguimiento y registrar datos de temperatura a lo largo del tiempo, proporcionándole información valiosa sobre el rendimiento de su horno y los resultados de sus experimentos.

Además, considere los hornos equipados con tecnologías de ahorro energético como cámaras de fibra cerámica que ofrecen tiempos de calentamiento más rápidos y un menor consumo de energía en comparación con las cámaras tradicionales de ladrillo refractario. Estas características no sólo reducen los costes operativos, sino que también contribuyen a un entorno de laboratorio más sostenible.

Evaluando cuidadosamente estas características adicionales, puede seleccionar un horno de mufla que no sólo satisfaga sus necesidades experimentales, sino que también mejore la eficiencia y eficacia general de su trabajo de laboratorio.

Productos relacionados

- Horno de Mufla de 1200℃ para Laboratorio

- Horno de mufla de 1700℃ para laboratorio

- Horno de mufla de 1400 ℃ para laboratorio

- Horno de mufla de 1800℃ para laboratorio

- Crisol Cerámico de Alúmina Avanzada Fina de Ingeniería Al2O3 para Horno Mufla de Laboratorio

Artículos relacionados

- Comparación de características y especificaciones de hornos de laboratorio: una guía

- Guía completa de hornos de mufla: Aplicaciones, tipos y mantenimiento

- Cómo elegir el mejor horno de porcelana Dental

- Guía completa de hornos de mufla: Tipos, usos y mantenimiento

- Exploración del uso de un horno de cámara para aplicaciones industriales y de laboratorio