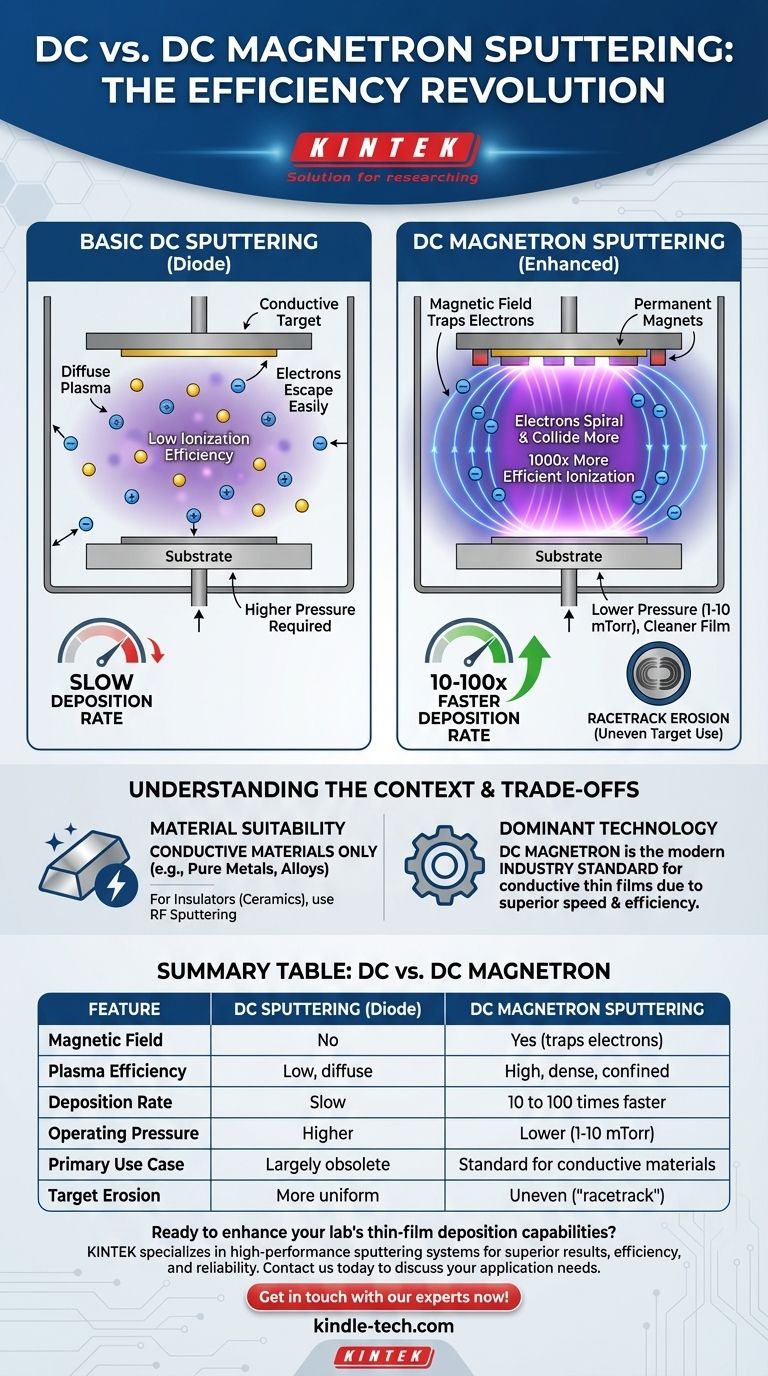

La diferencia fundamental es la adición de un potente campo magnético directamente detrás del material objetivo en el sputtering de magnetrón de CC. Si bien ambos métodos utilizan un voltaje de CC para crear un plasma y bombardear un objetivo, el campo magnético del magnetrón atrapa electrones cerca de la superficie del objetivo. Esta confinación aumenta drásticamente la eficiencia del plasma, lo que conduce a tasas de deposición significativamente más altas.

En esencia, el sputtering de magnetrón de CC no es un proceso fundamentalmente diferente, sino más bien una mejora crítica del sputtering de CC básico. El uso de imanes resuelve la ineficiencia principal del método original, convirtiéndolo en el estándar moderno para depositar películas delgadas conductoras.

La base: cómo funciona el sputtering de CC básico

El método original, a menudo llamado sputtering de diodo de CC, es la forma más simple de la tecnología. Comprender sus limitaciones es clave para apreciar por qué se desarrolló la mejora del magnetrón.

El proceso central

Se aplica un alto voltaje de CC entre dos electrodos en una cámara de vacío llena de un gas inerte, generalmente Argón. El material objetivo (la fuente de recubrimiento) actúa como cátodo, y el sustrato (el objeto a recubrir) se coloca en el ánodo. El voltaje enciende el gas en un plasma, creando iones de Argón cargados positivamente que son acelerados hacia el objetivo cargado negativamente, expulsando átomos que luego se depositan en el sustrato.

La limitación principal: ineficiencia

En esta configuración básica, el plasma es difuso e ineficiente. Los electrones libres creados en el proceso pueden viajar directamente al ánodo o a las paredes de la cámara sin colisionar con los átomos de Argón. Esto da como resultado un plasma de baja densidad, que requiere presiones de gas más altas para sostenerse, lo que a su vez conduce a una baja velocidad de deposición y un calentamiento no deseado del sustrato.

La mejora: introducción del magnetrón

El sputtering de magnetrón de CC aborda la ineficiencia central del método de diodo al agregar un conjunto de imanes permanentes detrás del cátodo objetivo.

El papel del campo magnético

Este campo magnético se proyecta de manera que atrapa los electrones libres en una trayectoria espiral directamente frente a la superficie del objetivo. En lugar de escapar, estos electrones se ven obligados a recorrer una distancia mucho mayor dentro del plasma.

El resultado: mayor ionización

La trayectoria extendida de los electrones atrapados aumenta drásticamente la probabilidad de que colisionen e ionizen átomos de Argón neutros. Este proceso es miles de veces más eficiente para crear iones que el sputtering de CC básico.

El impacto en el rendimiento

Esta ionización hiper-eficiente crea un plasma muy denso e intenso confinado a la región directamente frente al objetivo. Esta densa nube de iones bombardea el objetivo con mucha mayor intensidad, lo que resulta en una tasa de sputtering de 10 a 100 veces mayor que el sputtering de CC básico. Esto permite que el proceso se ejecute a presiones y voltajes más bajos.

Comprensión de las compensaciones y el contexto

Si bien el sputtering de magnetrón de CC es la tecnología dominante, es importante comprender sus características y dónde encaja en el panorama más amplio de las tecnologías de sputtering.

Tasa de deposición y eficiencia

Esta es la ventaja más significativa. El sputtering de magnetrón de CC ha reemplazado en gran medida al sputtering de diodo de CC básico en casi todas las aplicaciones industriales y de investigación debido a su velocidad y eficiencia muy superiores.

Presión y voltaje del sistema

Debido a que el campo magnético hace que el plasma se autosostenga, los sistemas de magnetrón pueden operar a presiones de gas mucho más bajas (típicamente 1-10 mTorr). Esto da como resultado un entorno de deposición más limpio y películas de mayor calidad con menor incorporación de gas. También opera a un voltaje más bajo (por debajo de 1000 V) pero con una corriente más alta.

Erosión del "carril de carreras" del objetivo

Una compensación notable es que el plasma confinado causa una erosión desigual del material objetivo. El área de bombardeo de plasma más intensa forma un surco distinto, a menudo llamado "carril de carreras" (racetrack), que limita la porción utilizable del material objetivo.

Una nota sobre el tipo de material

Tanto el sputtering de CC como el sputtering de magnetrón de CC solo son efectivos para materiales objetivo conductores, como los metales puros. Si se utiliza un material no conductor (aislante o dieléctrico) como una cerámica, los iones positivos que golpean el objetivo acumularán una carga positiva, neutralizando finalmente el voltaje y deteniendo el proceso. Para estos materiales, se requiere el sputtering de radiofrecuencia (RF).

Tomar la decisión correcta para su proceso

Su elección de tecnología de sputtering está dictada casi por completo por el material que tiene la intención de depositar.

- Si su enfoque principal es depositar una película conductora (p. ej., metales, aleaciones): El sputtering de magnetrón de CC es el estándar industrial moderno debido a su alta velocidad, eficiencia y rentabilidad.

- Si su enfoque principal es depositar una película aislante (p. ej., óxidos, nitruros, cerámicas): Debe utilizar el sputtering de RF, que casi siempre se mejora con una matriz de magnetrones (convirtiéndose en sputtering de magnetrón de RF) para los mismos beneficios de eficiencia.

- Si está trabajando con un sistema heredado o una configuración altamente especializada: Es posible que encuentre el sputtering de diodo de CC básico, pero ha sido casi completamente reemplazado para aplicaciones prácticas debido a su baja tasa de deposición.

En última instancia, el magnetrón es la innovación clave que transformó el sputtering de una técnica de laboratorio lenta a un proceso de fabricación industrial de alto rendimiento.

Tabla de resumen:

| Característica | Sputtering de CC (Diodo) | Sputtering de magnetrón de CC |

|---|---|---|

| Campo magnético | No | Sí (atrapa electrones) |

| Eficiencia del plasma | Baja, difusa | Alta, densa, confinada |

| Tasa de deposición | Lenta | 10 a 100 veces más rápida |

| Presión de operación | Más alta | Más baja (1-10 mTorr) |

| Caso de uso principal | En gran parte obsoleto | Estándar para materiales conductores |

| Erosión del objetivo | Más uniforme | Desigual (erosión de 'carril de carreras') |

¿Listo para mejorar las capacidades de deposición de películas delgadas de su laboratorio?

KINTEK se especializa en sistemas de sputtering de alto rendimiento y equipos de laboratorio. Ya sea que esté depositando metales conductores o necesite soluciones de RF avanzadas para materiales aislantes, nuestra experiencia garantiza que obtenga el equipo adecuado para resultados superiores, eficiencia y confiabilidad.

Contáctenos hoy para discutir las necesidades específicas de su aplicación y descubrir cómo KINTEK puede respaldar el éxito de su laboratorio.

¡Póngase en contacto con nuestros expertos ahora!

Guía Visual

Productos relacionados

- Sistema RF PECVD Deposición Química de Vapor Mejorada por Plasma de Radiofrecuencia RF PECVD

- Equipo de Deposición Química de Vapor CVD Sistema Horno de Tubo PECVD Deslizante con Gasificador Líquido Máquina PECVD

- Prensa Térmica Hidráulica Eléctrica Calefactada al Vacío para Laboratorio

- Horno de Tubo de CVD de Cámara Dividida con Sistema de Deposición Química de Vapor y Estación de Vacío

- Horno de Sinterización y Tratamiento Térmico al Vacío con Presión de Aire de 9MPa

La gente también pregunta

- ¿Qué es el CVD de plasma? Descubra la deposición de películas delgadas a baja temperatura para materiales sensibles

- ¿Por qué el PECVD utiliza comúnmente una entrada de potencia de RF? Para la deposición precisa de películas delgadas a baja temperatura

- ¿Cómo crea el plasma la energía de radiofrecuencia (RF)? Logre un plasma estable y de alta densidad para sus aplicaciones

- ¿Cómo funciona la deposición de vapor por plasma? Una solución de recubrimiento a baja temperatura para materiales sensibles

- ¿Qué es el método de deposición química de vapor activado por plasma? Una solución de baja temperatura para recubrimientos avanzados