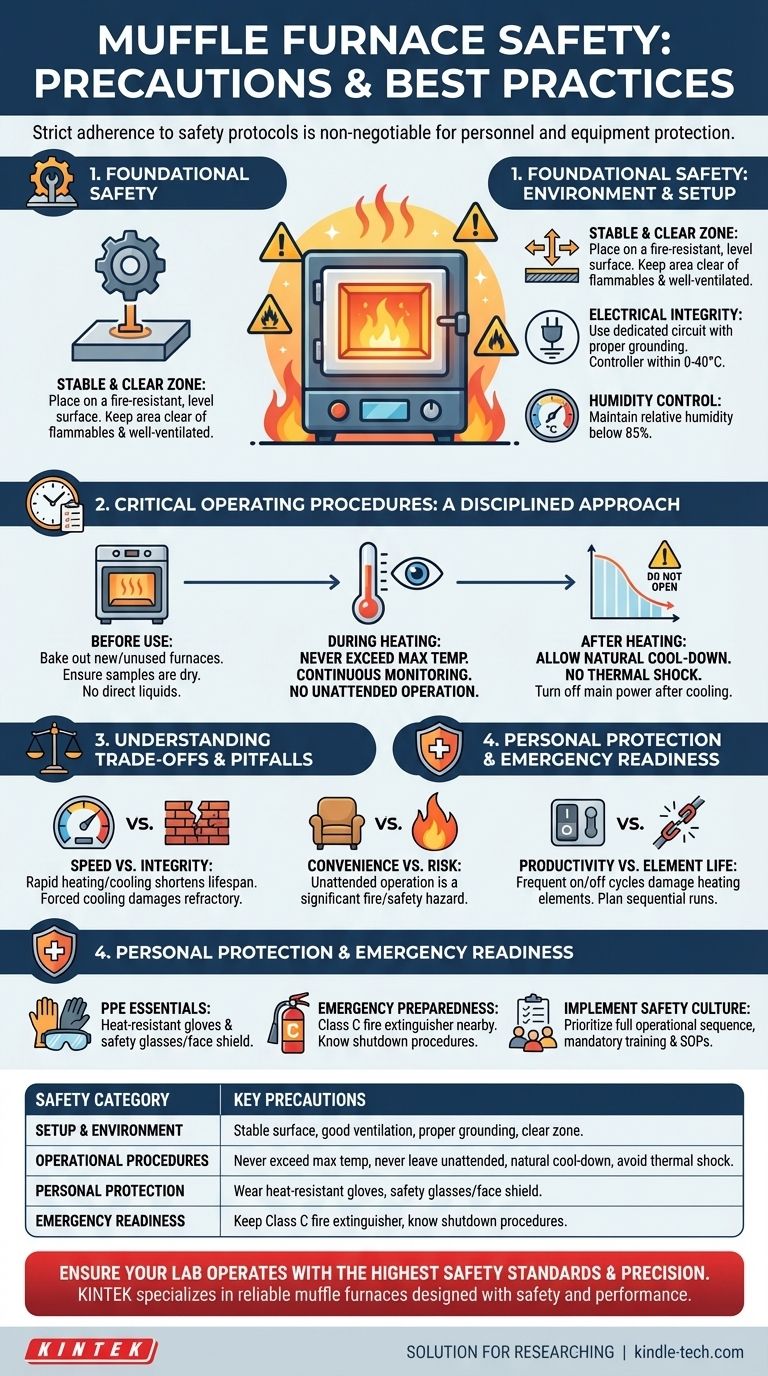

La adhesión estricta a los protocolos de seguridad no es negociable al operar un horno mufla. Las temperaturas extremas presentan riesgos significativos, y las precauciones deben cubrir la protección personal, los procedimientos operativos correctos y los controles ambientales. Esto implica usar equipo resistente al calor apropiado, asegurar que el horno esté sobre una superficie estable y despejada, nunca exceder su temperatura nominal y permitir que se enfríe naturalmente antes de abrir la puerta.

Un horno mufla no es un aparato que deba dejarse sin supervisión. La seguridad efectiva es un proceso sistemático que comienza antes de encender el horno y termina solo después de que se haya enfriado por completo, con el objetivo principal de controlar el calor extremo y prevenir reacciones imprevistas de los materiales.

Seguridad Fundamental: Entorno y Configuración

La configuración adecuada es la primera línea de defensa contra accidentes. La ubicación física y la condición del horno y sus alrededores son fundamentales para una operación segura.

Asegurar la Ubicación del Horno

El horno debe colocarse sobre una superficie estable, nivelada y resistente al fuego, como una plataforma de hormigón. Esto evita que se vuelque y asegura que pueda soportar el peso.

Asegúrese de que el área esté bien ventilada para disipar el calor y cualquier posible humo de los materiales que se están procesando.

Conexiones y Conexión a Tierra Eléctrica

El horno requiere un circuito eléctrico dedicado con los enchufes, tomas de corriente y fusibles correctos para su clasificación de potencia. La conexión a tierra adecuada es obligatoria para prevenir descargas eléctricas.

La unidad de control debe operar dentro de su rango de temperatura ambiente especificado, generalmente de 0 a 40 °C (32 a 104 °F), y no debe colocarse directamente encima del horno.

Mantener una Zona Despejada y Segura

El entorno debe estar libre de materiales inflamables, explosivos o corrosivos. Mantenga una distancia considerable alrededor del horno, ya que su carcasa exterior se calienta mucho durante la operación.

La humedad relativa debe mantenerse por debajo del 85% para proteger los componentes eléctricos y los materiales refractarios.

Procedimientos Operativos Críticos

Un enfoque disciplinado y paso a paso de la operación minimiza los riesgos tanto para el usuario como para el equipo.

Antes de Comenzar: Verificaciones Previas al Uso

Si un horno es nuevo o no se ha utilizado durante mucho tiempo, primero debe "curarse" (baked out). Esto implica un proceso de calentamiento lento y gradual para expulsar cualquier humedad absorbida del revestimiento refractario, evitando que se agriete.

Confirme que todas las muestras estén secas. Nunca coloque líquidos directamente en el horno. Los materiales que puedan liberar grasa o gases volátiles deben calentarse en un recipiente sellado o ventilado adecuadamente.

Durante el Calentamiento: Control y Monitoreo

Nunca exceda la temperatura máxima nominal del horno, ya que esto dañará los elementos calefactores. Evite operar a la temperatura máxima durante períodos prolongados.

El horno debe ser monitoreado durante todo el ciclo de calentamiento. Una falla en el controlador de temperatura podría provocar un evento térmico descontrolado. Nunca deje un horno funcionando sin supervisión, especialmente durante la noche.

Cargue y descargue las muestras solo cuando el horno esté apagado y a una temperatura segura. Evite sobrecargar la cámara del horno, ya que esto puede provocar un calentamiento desigual.

Después del Calentamiento: El Proceso de Enfriamiento

No abra la puerta del horno cuando la temperatura interna sea alta (por ejemplo, superior a 600 °C). El cambio repentino de temperatura, conocido como choque térmico, puede agrietar el revestimiento del horno y hacer estallar las muestras.

Permita siempre que el horno se enfríe de forma natural. Nunca intente acelerar el enfriamiento abriendo la puerta o introduciendo aire frío.

Una vez que el experimento haya finalizado y el horno se esté enfriando, apague la fuente de alimentación principal. Para el almacenamiento, mantenga la puerta del horno cerrada para proteger los materiales refractarios de la absorción de humedad atmosférica.

Comprensión de las Compensaciones y Errores Comunes

Las desviaciones aparentemente menores del procedimiento pueden tener consecuencias significativas para la seguridad y la longevidad del equipo.

Velocidad frente a Integridad del Equipo

El error más común es sacrificar el procedimiento adecuado en aras de la velocidad. El calentamiento o enfriamiento rápido ahorra tiempo, pero introduce una tensión inmensa en la cámara del horno y los elementos calefactores, acortando drásticamente su vida útil. El enfriamiento forzado es una causa principal de daños al refractario.

Conveniencia frente a Riesgo Inherente

Dejar un horno sin supervisión es una apuesta significativa. Aunque es conveniente, elimina por completo su capacidad de responder a un mal funcionamiento del controlador, una sobretensión o una reacción inesperada de su muestra, creando un grave peligro de incendio y seguridad.

Productividad frente a Vida Útil del Elemento

Los ciclos frecuentes de encendido/apagado pueden ser perjudiciales. Cada vez que los elementos calefactores se enfrían, la capa de óxido protectora que se forma sobre ellos puede desprenderse. El ciclo repetido de la energía acorta la vida útil de estos componentes críticos. A menudo es mejor planificar los experimentos para que se ejecuten secuencialmente en lugar de apagar el horno entre ejecuciones cortas.

Protección Personal y Preparación para Emergencias

Su seguridad personal depende de usar el equipo adecuado y estar preparado para lo inesperado.

Equipo de Protección Personal (EPP)

Use siempre guantes resistentes al calor y gafas de seguridad o un protector facial cuando trabaje cerca del horno, incluso si no está abriendo la puerta. El tipo de guante debe estar clasificado para las temperaturas con las que está trabajando.

Preparación para Emergencias

Asegúrese de que haya un extintor de incendios apropiado para incendios eléctricos (Clase C) ubicado cerca del horno mufla.

Todos los operadores deben conocer los procedimientos de apagado de emergencia. Si nota alguna anormalidad —como ruidos extraños, humo o lecturas de temperatura erráticas— apague la energía inmediatamente y no utilice el horno hasta que haya sido inspeccionado por personal cualificado.

Implementación de una Cultura de Seguridad

Para garantizar resultados seguros y fiables, la seguridad debe ser una responsabilidad compartida basada en procedimientos claros y una formación adecuada.

- Si su enfoque principal es la operación práctica: Priorice siempre la secuencia operativa completa, desde las verificaciones previas al uso hasta el enfriamiento natural, y nunca trabaje sin el EPP correcto.

- Si su enfoque principal es la gestión del laboratorio: Implemente capacitación obligatoria, cree procedimientos operativos estándar (SOP) claros y haga cumplir una política estricta contra la operación sin supervisión.

En última instancia, la operación disciplinada y segura es la base que permite un trabajo preciso, repetible y exitoso con un horno mufla.

Tabla Resumen:

| Categoría de Seguridad | Precauciones Clave |

|---|---|

| Configuración y Entorno | Superficie estable y resistente al fuego; buena ventilación; conexión a tierra adecuada; libre de inflamables. |

| Procedimientos Operativos | Nunca exceder la temperatura máxima; nunca dejar sin supervisión; permitir enfriamiento natural; evitar el choque térmico. |

| Protección Personal | Usar siempre guantes resistentes al calor y gafas de seguridad/protector facial. |

| Preparación para Emergencias | Tener cerca un extintor de incendios Clase C; conocer los procedimientos de apagado de emergencia. |

Asegure que su laboratorio opere con los más altos estándares de seguridad y precisión. KINTEK se especializa en hornos mufla y equipos de laboratorio fiables y de alta calidad diseñados pensando en la seguridad y el rendimiento. Nuestros expertos pueden ayudarle a seleccionar el equipo adecuado y proporcionar orientación sobre su operación segura. Contáctenos hoy para discutir sus necesidades de laboratorio y cómo podemos apoyar su éxito con soluciones duraderas, seguras y eficientes.

Guía Visual

Productos relacionados

- Horno de Mufla de Laboratorio con Elevación Inferior

- Horno de mufla de 1800℃ para laboratorio

- Horno de mufla de 1700℃ para laboratorio

- Horno de mufla de 1400 ℃ para laboratorio

- Horno de Tubo de Laboratorio de Alta Temperatura de 1400℃ con Tubo de Alúmina

La gente también pregunta

- ¿Cómo se comprueba el contenido de cenizas de un horno mufla? Una guía paso a paso para el análisis de materiales

- ¿Para qué se utiliza un horno de mufla? Logre un procesamiento a alta temperatura con pureza

- ¿Cómo se mide el contenido de cenizas? Elija el método correcto para obtener resultados precisos

- ¿Para qué se utiliza un horno mufla para determinar? Mida con precisión cenizas, materia volátil y humedad

- ¿Qué es el revestimiento de horno? El sistema de ingeniería que protege sus procesos a alta temperatura