En esencia, la fusión por arco de plasma (PAM) es un proceso altamente especializado que utiliza un chorro de gas ionizado —un plasma— para fundir y refinar metales. A diferencia de la fusión convencional, que simplemente licúa un material, la PAM es una tecnología de horno de temperatura ultra alta diseñada para producir lingotes excepcionalmente limpios y de alta calidad a partir de metales reactivos y de alto rendimiento como el titanio y las superaleaciones.

La fusión por arco de plasma no es solo un proceso de fusión; es un proceso de purificación. Su valor principal radica en su capacidad para eliminar contaminantes y lograr un control metalúrgico preciso, lo que lo hace indispensable para aplicaciones críticas en las industrias aeroespacial, médica y de defensa.

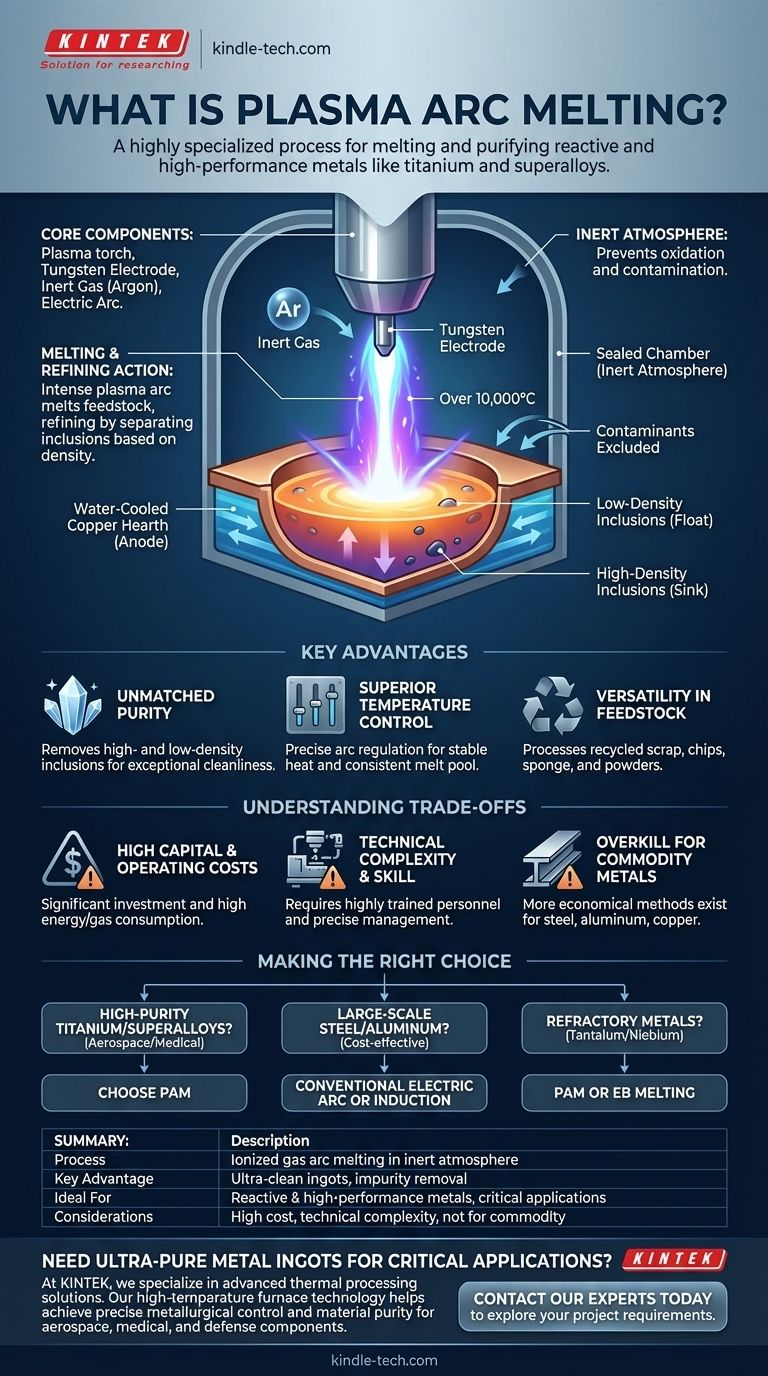

Cómo funciona la fusión por arco de plasma

Comprender el proceso PAM requiere observar cómo genera y utiliza un arco de plasma controlado dentro de un entorno inerte para lograr resultados que otros métodos no pueden.

Los componentes centrales

Un horno de arco de plasma consta de una o más antorchas de plasma, que actúan como fuente de calor. Una antorcha utiliza un electrodo de tungsteno (cátodo) a través del cual se hace pasar un gas inerte, típicamente argón. Un potente arco eléctrico ioniza este gas, convirtiéndolo en un chorro de plasma sobrecalentado.

La acción de fusión y refinación

El material a fundir se coloca en un hogar o crisol de cobre refrigerado por agua, que actúa como ánodo. El arco de plasma se dirige hacia el material, con temperaturas en el núcleo del arco que alcanzan más de 10,000 °C. Esta energía intensa y enfocada funde rápidamente la materia prima.

A medida que el metal se licúa en un baño fundido, el proceso comienza su trabajo de refinación. Las impurezas más ligeras, conocidas como inclusiones de baja densidad, flotan en la superficie y pueden consolidarse, mientras que las impurezas más pesadas de alta densidad se hunden y quedan atrapadas en el fondo del lingote solidificado.

La importancia de la atmósfera inerte

Todo el proceso se lleva a cabo en una cámara sellada llena de un gas inerte. Esta atmósfera controlada es fundamental porque evita que el metal fundido altamente reactivo se contamine con oxígeno y nitrógeno del aire, lo que degradaría sus propiedades.

Ventajas clave del proceso PAM

Los ingenieros y metalúrgicos eligen PAM cuando la calidad final del material no es negociable. Sus ventajas se centran en la pureza y el control.

Pureza y limpieza inigualables

Al eliminar eficazmente las inclusiones tanto de alta como de baja densidad, PAM produce un lingote de metal con una limpieza excepcional. Esto es vital para materiales como las aleaciones de titanio, donde incluso las impurezas microscópicas pueden provocar una falla por fatiga prematura en una álabes de turbina de motor a reacción o un implante médico.

Control superior de temperatura y proceso

La salida de energía de la antorcha de plasma se puede regular con precisión, independientemente de la presión de funcionamiento dentro del horno. Esto proporciona una fuente de calor muy estable y controlable, lo que permite una piscina de fusión constante y un producto final predecible y uniforme.

Versatilidad en el material de alimentación

Los hornos PAM son flexibles y pueden procesar una amplia gama de formas de materia prima. Esto incluye desde chatarra reciclada y virutas mecanizadas hasta esponja metálica y polvos en bruto, lo que permite un uso eficiente de los recursos.

Comprensión de las compensaciones y limitaciones

Aunque es potente, la fusión por arco de plasma no es una solución universal. Su naturaleza especializada conlleva consideraciones significativas.

Altos costos de capital y operativos

Los hornos PAM son sistemas complejos de ingeniería de precisión que representan una inversión de capital significativa. También tienen altos costos operativos debido a su consumo de energía eléctrica y grandes cantidades de gas inerte.

Complejidad técnica y requisito de habilidad

Operar un horno PAM no es una tarea sencilla. Requiere personal altamente capacitado que pueda gestionar el delicado equilibrio entre la potencia del arco, el flujo de gas, las tasas de enfriamiento y la progresión de la fusión para garantizar un resultado exitoso.

Es excesivo para metales básicos

Para el acero al carbono estándar, el aluminio o el cobre, los métodos mucho más baratos y de mayor volumen, como los hornos de inducción o los hornos de arco eléctrico, son mucho más económicos. La PAM se reserva para materiales de alto valor donde sus beneficios de refinación justifican el costo.

Tomar la decisión correcta para su objetivo

La selección de una tecnología de fusión depende completamente de su material y requisitos de rendimiento. La PAM es una herramienta para lograr los más altos estándares de pureza metalúrgica.

- Si su enfoque principal es producir titanio o superaleaciones de alta pureza para uso aeroespacial o médico: La PAM es el estándar de la industria, que ofrece una limpieza y un control de propiedades inigualables.

- Si su enfoque principal es la producción a gran escala y rentable de acero o aluminio: Los hornos de arco eléctrico o de inducción convencionales son la opción apropiada y económica.

- Si su enfoque principal es fundir metales refractarios como tántalo o niobio: La PAM es un candidato principal, que compite con la fusión por haz de electrones (EB), que opera en alto vacío.

En última instancia, comprender las capacidades de la fusión por arco de plasma le permite crear materiales que cumplen con las especificaciones más exigentes con una calidad intransigente.

Tabla de resumen:

| Característica | Descripción |

|---|---|

| Proceso | Utiliza un arco de plasma de gas ionizado para fundir y refinar metales en una atmósfera inerte. |

| Ventaja clave | Produce lingotes ultralimpios al eliminar impurezas tanto de alta como de baja densidad. |

| Ideal para | Metales reactivos y de alto rendimiento (titanio, superaleaciones), aeroespacial, implantes médicos. |

| Consideraciones | Altos costos de capital/operativos, complejidad técnica, no para metales básicos. |

¿Necesita producir lingotes de metal ultrapuros para aplicaciones críticas?

En KINTEK, nos especializamos en soluciones avanzadas de procesamiento térmico para entornos exigentes de laboratorio e I+D. Nuestra experiencia en tecnología de hornos de alta temperatura puede ayudarle a lograr el control metalúrgico preciso y la pureza del material requeridos para componentes aeroespaciales, médicos y de defensa.

Analicemos cómo nuestro equipo especializado puede satisfacer sus desafíos específicos de materiales. Póngase en contacto con nuestros expertos hoy mismo para explorar los requisitos de su proyecto.

Guía Visual

Productos relacionados

- Horno de Fusión por Inducción al Vacío para Fusión por Inducción

- Horno Tubular de Laboratorio de Alta Temperatura de 1700℃ con Tubo de Alúmina

- Horno de Tubo de Laboratorio de Alta Temperatura de 1400℃ con Tubo de Alúmina

- Horno de Fusión por Inducción al Vacío a Escala de Laboratorio

- Horno de tubo de laboratorio vertical

La gente también pregunta

- ¿Cuáles son los diferentes métodos de fusión? Una guía para elegir el horno industrial adecuado

- ¿Cuál es la diferencia entre VAR y VIM? Variables heredadas de Vimscript vs. API moderna de Neovim

- ¿Qué es una máquina de pulverización catódica magnetrónica? Deposición de películas delgadas de precisión para materiales avanzados

- ¿Para qué se utilizan los sistemas de pulverización catódica? Una guía para la deposición avanzada de películas delgadas

- ¿Cómo funciona una máquina de pulverización catódica (sputtering)? Logre precisión a nivel atómico para sus recubrimientos